Industrial demister pads are critical gas–liquid separation devices engineered to remove entrained liquid droplets from process gas streams, protecting downstream equipment and maintaining operational efficiency. When deployed in harsh chemical environments, demister mist eliminators routinely handle high mist loads and entrained contaminants, which can accumulate over time and degrade separation efficiency if not properly maintained.

Implementing a systematic cleaning and maintenance program is essential to sustain demister pad performance, prevent excessive pressure drop, and maximize service life. By employing optimized cleaning protocols and preventive practices, industrial facilities can achieve consistent droplet removal across chemical processing units, petrochemical plants, refineries, and other demanding industrial applications.

Understanding the Working Principle of a Demister Pad

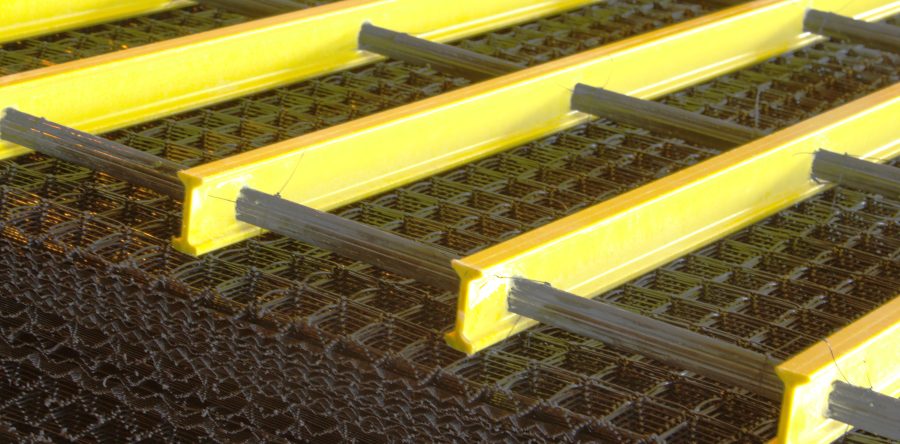

A demister mist eliminator operates by directing gas streams through a structured matrix of knitted wire mesh or engineered fiber media. Entrained droplets collide with the mesh and coalesce into larger drops, which drain by gravity back into the process. Optimal separation efficiency relies on clean mesh surfaces, uniform gas distribution, and proper mechanical installation.

1. Common Causes of Demister Pad Fouling

Several process conditions contribute to demister pad fouling:

- Accumulation of dust, particulate matter, or solid residues

- High-viscosity liquid carryover or polymerizing fluids

- Chemical reactions producing sticky or resinous deposits

- Condensed oil or hydrocarbon mist

- Inorganic scaling from mineral-laden process streams

Identifying the primary fouling sources is essential for tailoring cleaning schedules and upstream separation strategies, ensuring demister pads continue to perform effectively.

2. Warning Signs of a Fouled Demister Mist Eliminator

Signs of decreased performance in a demister mist eliminator include:

- Increased differential pressure across the vessel

- Uneven or reduced gas flow distribution

- Visible buildup or encrustation on the demister pad mesh

- Poor mist removal leading to higher liquid carryover

These operational indicators signal the need for inspection, cleaning, or replacement to maintain reliable droplet separation.

3. Step-by-Step Cleaning Procedure for Demister Pads

Cleaning procedures vary depending on contaminant type, but generally include:

- Removal from Housing: Extract the demister pad carefully to avoid mesh distortion.

- Mechanical Cleaning: Gently brush or use low-pressure compressed air to remove loose particles.

- Water or Chemical Washing: Apply warm water, steam, or approved cleaning solutions for viscous or chemical deposits. Solvent-based cleaners may be necessary for hydrocarbon residues.

- Rinsing and Drying: Thoroughly rinse to remove residual cleaning agents and allow complete drying before reinstallation.

- Inspection Before Reinstallation: Check for corrosion, deformation, or damaged mesh layers. Replace compromised sections to ensure reliable performance.

4. Preventive Measures to Minimize Fouling and Extend Service Life

To optimize the lifespan of demister pads:

- Install pre-filters or upstream separators to reduce contaminant load.

- Maintain consistent process conditions to avoid reactive buildup.

- Select corrosion-resistant materials for aggressive chemical environments.

- Ensure proper airflow and liquid drainage to prevent mesh saturation.

A proactive maintenance strategy reduces fouling frequency and enhances the long-term efficiency of the demister mist eliminator.

5. Cleaning Frequency and Maintenance Scheduling

The cleaning interval for demister pads depends on gas composition, mist load, and process severity. High-contaminant streams may require monthly maintenance, whereas cleaner applications may only need quarterly or semi-annual servicing. Monitoring pressure-drop trends and pad condition ensures an optimized maintenance schedule, minimizing downtime.

6. Working with Trusted Demister Pad Manufacturers and Suppliers

Partnering with experienced demister pad manufacturers and demister pad suppliers ensures access to high-quality mesh materials, engineered media, and technical guidance. Reputable manufacturers provide recommendations for proper installation, cleaning protocols, and material selection tailored to thermal, chemical, and mechanical operating conditions. This expertise is critical to maintaining long-term demister mist eliminator reliability and performance.

Best Practices for Long-Term Demister Pad Performance

- Conduct regular visual inspections for fouling, corrosion, or mechanical wear.

- Keep detailed maintenance logs to monitor performance trends.

- Replace worn or damaged sections promptly to prevent downstream contamination.

- Align cleaning routines with process fluctuations or seasonal variations.

- Ensure proper seating and alignment during installation to avoid bypass or flow maldistribution.

Adhering to these best practices maintains consistent droplet separation and reduces the risk of unplanned downtime.

Also read: Demister Pads vs. Mist Eliminators: What’s the Best Solution for Your Process?

Consistent Maintenance Ensures Reliable Mist Elimination

The long-term performance of demister pads is directly linked to thorough cleaning, preventive maintenance, and the use of durable, high-quality components. Kimre, a trusted leader among demister pad manufacturers, delivers engineered demister mist eliminators and replacement pads designed for demanding industrial environments.

For optimized separation efficiency, durable demister pads, and technical support from experienced demister pad suppliers, contact Kimre™ Clean Air Technology for tailored maintenance guidance and high-quality replacement components.