An Engineering Perspective on Contamination Control in Industrial Environments

In high-demand industrial operations—particularly those involving metalworking, thermoplastics processing, or petrochemical synthesis—the generation of airborne oil mist, fine aerosols, and vapor-phase lubricants is an inevitable consequence of elevated temperatures, high-speed rotation, and turbulent fluid contact. Without a robust mitigation strategy, these submicron particles and oil vapors accumulate on sensitive components, catalyzing premature mechanical degradation, electronic failures, and process variability.

A properly engineered oil mist collector, designed to operate either at the point source or within a centralized ventilation system, plays a critical role in controlling these emissions. By efficiently capturing oil mist, vaporized lubricants, and condensable hydrocarbon species, these systems significantly reduce contamination, extend the operational lifespan of assets, and enhance plant safety.

The Mechanism Behind Machinery Degradation

Oil mist forms when lubricants or process fluids atomize due to shear forces, flashing, or high-temperature vaporization. These airborne contaminants, once liberated, become entrained in ventilation currents and disperse across equipment surfaces and control systems. The implications are multi-faceted:

-

Electronic Controls: Deposition on PCB substrates or optical sensors can lead to signal interference, short-circuiting, or system drift.

-

Rotating Equipment: Bearings, shaft seals, and linear guides accumulate dust-bound oil mist, accelerating wear via tribological abrasion.

-

Thermal Management Systems: Fouling of heat exchangers or coolant filtration elements restricts flow rates and degrades thermal conductivity, increasing the risk of overheating.

For continuous or high-precision operations, such contamination leads to increased unplanned downtime, unscheduled maintenance, and non-compliance with ISO clean manufacturing standards.

Also Read :

Why Oil Mist Removal Is Important?

Understanding The Selection Of Mist Eliminators

How Kimre’s Mist Eliminators Ensure Clean Air in Oil Frying Processes

Engineering the Solution: Oil Mist Collectors and Separators

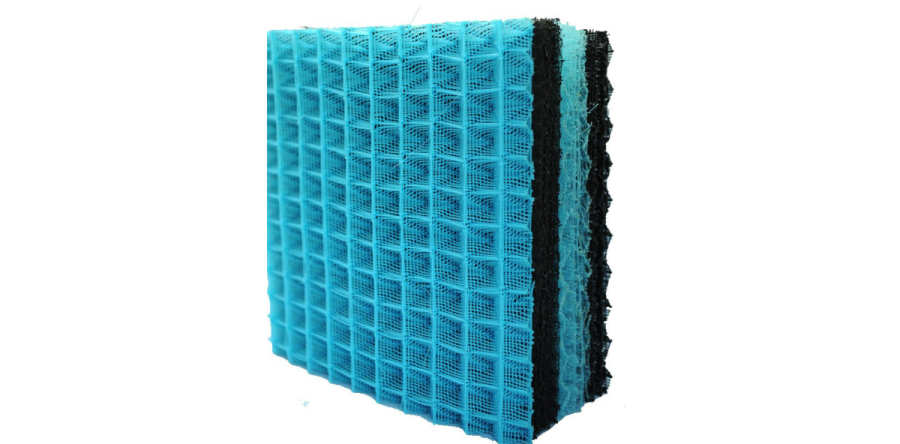

An oil mist separator, also known in specialized applications as an oil vapor separator, functions by removing both liquid-phase and vapor-phase contaminants from process air streams. The core principles involve impaction, diffusion, and coalescence, often deployed within a high-efficiency filter media such as Kimre’s proprietary fiber bed designs.

-

Impaction and Diffusion: Submicron particles collide with densely packed filter fibers and are trapped via Brownian motion and inertial forces.

-

Coalescence: Collected droplets agglomerate and drain as liquid, which can be recovered or safely disposed of.

-

Vapour Control: Advanced separators further remove semi-volatile organic compounds (SVOCs) and condensable oil vapours, which would otherwise evade capture and redeposit downstream.

The result is a high-efficiency air purification system that prevents the formation of surface oil films, preserves process integrity, and ensures compliance with OSHA and EPA particulate and VOC exposure limits.

Operational and Economic Benefits

Implementing a high-performance oil mist collector system yields measurable returns in system longevity and operational continuity:

-

Reduced Abrasion and Component Wear: Less particulate-oil amalgam means longer-lasting drive trains and pneumatic components.

-

Improved Automation Accuracy: Clean optics and sensors maintain calibration and reliability in vision-guided or feedback-controlled processes.

-

Lower Maintenance Frequency: Downtime for manual degreasing, filter replacement, and electronics cleaning is minimized.

-

Enhanced Workplace Safety: Oil film on walking surfaces is a known slip hazard and can be effectively mitigated with mist separation.

Moreover, clean air environments improve HVAC efficiency, lower facility energy consumption, and reduce corrosion-related maintenance in electrical enclosures and control cabinets.

Applicability in Demanding Manufacturing Environments

Kimre’s engineered solutions for oil mist separation are particularly effective in high-output environments, including:

-

CNC and lathe operations with high-speed spindles

-

Hot plastic extrusion and injection molding processes

-

Food industry frying and oil-recirculation systems

-

Large-scale gearboxes and turbine lubrication skids

In such applications, an oil mist collector must not only perform consistently but do so under challenging flow conditions, variable particulate loads, and with minimal pressure drop.

Built on Decades of Filtration Expertise

For over 50 years, Kimre has specialized in designing and manufacturing advanced mist elimination technologies for industrial and chemical process sectors. Our high-performance oil mist separators and oil vapor collectors are engineered to address the stringent demands of modern facilities—maximizing uptime, minimizing contaminant migration, and safeguarding both personnel and equipment.

Connect with our engineering team to evaluate your facility’s exposure to airborne oil contaminants and develop a tailored mist elimination strategy that ensures long-term reliability and compliance.