Mist Eliminators are essential components of wet scrubbers, making them an important factor to consider when selecting a wet scrubber for an industrial application. Mist eliminators, including those using mesh pads, are typically used to remove droplets of water or other liquids from a gas stream, thus improving the efficiency of a wet scrubber.

By effectively separating liquid from gas, mist eliminators help reduce emissions, protect downstream equipment, and maintain regulatory compliance.

What Do Mist Eliminators Do?

The role of mist eliminators in wet scrubbers is to control the particle size and mass flow of the scrubbed gas stream. This is done by trapping and removing droplets of water and other liquids that would otherwise be entrained in the gas stream. By removing these particles, mist eliminators help improve the efficiency and effectiveness of a wet scrubber.

Mist eliminators in wet scrubbers:

- Capture fine droplets of water, acid, or chemicals from exhaust streams

- Prevent liquid carryover into downstream equipment

- Reduce emissions for air pollution control compliance

- Improve scrubber efficiency and overall plant performance.

Without a properly designed mist eliminator, wet scrubbers can lose efficiency, leading to higher emissions and increased maintenance.

Common Types of Mist Eliminators

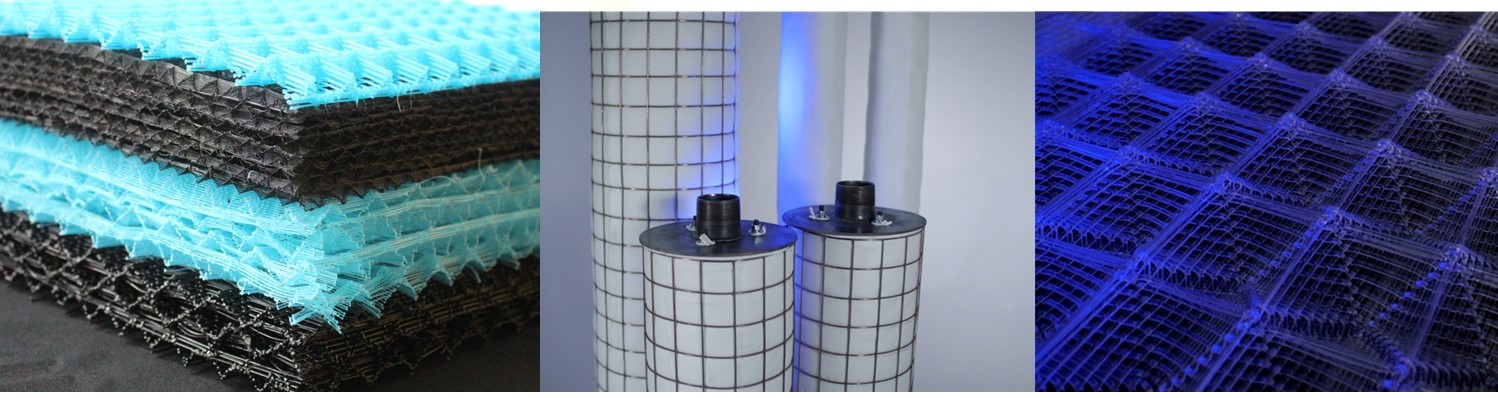

Common types of mist eliminators used in wet scrubbers include mesh, wire mesh mist eliminators, vane mist eliminators, and fiber bed mist eliminators.

Wire mesh mist eliminators are designed with two layers of mesh that trap and remove droplets from the gas stream. The outer layer is designed to disperse entrained droplets, while the inner layer is designed to capture the dispersed droplets and prevent them from re-entering the gas stream.

Vane mist eliminators use angled plates to disperse and capture droplets. These plates create turbulence in the gas stream, which causes droplets to be dispersed and removed from the stream by the vane edges.

Fiber bed mist eliminators use a bed of fibers to capture droplets as they pass through the bed.

Several designs are used depending on droplet size, flow conditions, and industry application:

1. Wire Mesh Mist Eliminators (Mesh Pads)

- Made of layers of woven wire or mesh

- Capture small to medium-sized droplets through inertial impaction and coalescence

- Ideal for general industrial use, chemical plants, and refineries

- Advantages: low pressure drop, cost-effective, customizable designs

2. Vane Mist Eliminators

- Use angled plates or vanes to redirect gas flow

- Droplets are forced to collide with vane surfaces and drain away

- Handle high gas velocities and large volumes

- Common in power plants, desalination, and petrochemical scrubbers

- Advantages: durable, suitable for higher liquid loads

3. Fiber Bed Mist Eliminators

- Dense mats of fine fibers capture submicron droplets and aerosols

- Often used for acid mist, sulfuric acid plants, and specialty chemical processes

- Provide very high removal efficiency for fine mists

- Advantages: excellent for meeting stringent emission standards

Selecting the Best Mist Eliminator

There are several advantages associated with using mist eliminators in wet scrubbers. Mist eliminators can reduce particle emissions by trapping and removing droplets from a gas stream, thus improving the efficiency and effectiveness of a wet scrubber. Additionally, mist eliminators can improve the quality of exhaust gases by preventing particles from being re-entrained in the gas stream.

When selecting a mist eliminator for a wet scrubber, there are several factors to consider.

Choosing the right mist eliminator depends on:

- Gas flow rate & velocity – higher flows may require vane types

- Droplet size distribution – submicron mist often requires fiber beds

- Pressure drop tolerance – critical for energy efficiency

- Space constraints – compact designs vs. larger pads

- Maintenance requirements – some designs are easier to clean and replace

A properly sized and engineered mist eliminator ensures maximum scrubber efficiency, reduced downtime, and long-term cost savings.

If you are looking for a high-quality mesh pad mist eliminator for your wet scrubber application, contact Kimre for more information about their wide selection of mesh pads.

Kimre’s mesh pads are designed for long-term use with low maintenance requirements, making them an ideal choice for industrial applications requiring effective mist elimination.