In industries where mist control is essential—such as chemical processing, petrochemical refining, and power generation—selecting the right mist elimination technology is critical to ensuring equipment protection, regulatory compliance, and operational efficiency.

Whether you're evaluating standard demister pads or more advanced mist eliminators, understanding the differences between these technologies is key to making the right choice for your application.

As experienced demister pad suppliers and demister pad manufacturers, Kimre helps industries across the globe implement high-performance mist elimination systems that deliver long-term value and reliability.

What Are Demister Pads?

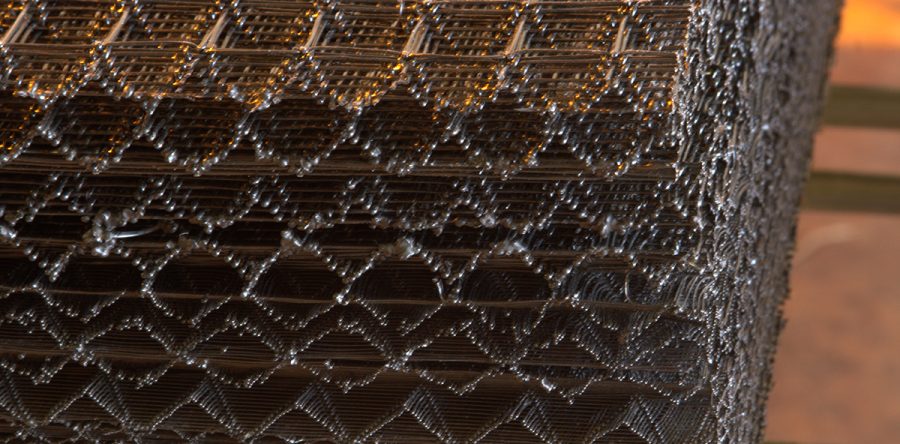

Demister pads, also known as mesh pad mist eliminators, are constructed from knitted wire mesh layered in various densities. As mist-laden vapor flows through the mesh, liquid droplets impact the filaments, coalesce, and drain by gravity, leaving the gas stream cleaner and drier.

Demister pads are widely used due to their:

- High removal efficiency for droplets larger than 5–10 microns

- Low pressure drop across the pad

- Compact design for space-constrained systems

- Ease of installation and minimal maintenance

Commonly used in horizontal and vertical vessels, industrial demister pads are an excellent fit for moderate flow conditions in processes such as desalination, gas scrubbing, and distillation.

What Are Mist Eliminators?

Mist eliminators are more advanced mist separation systems designed to handle higher velocities and capture finer droplets, including aerosols. These systems may use vane packs, fiber beds, or hybrid combinations to achieve higher separation efficiency than conventional wire mesh demisters.

Engineered mist eliminators are ideal for:

- Applications involving submicron droplet removal

- High-velocity gas streams

- Processes requiring strict emissions control

- Environments with fluctuating flow rates or high liquid loading

Mist eliminators offer tailored solutions for complex process conditions and are commonly found in acid plants, fertilizer production units, and power generation systems.

Demister Pads vs. Mist Eliminators: Key Comparison

| Feature | Demister Pads | Mist Eliminators |

| Construction | Knitted wire mesh | Vane packs, fiber beds, or hybrid designs |

| Droplet Size Removal | ≥5–10 microns | Submicron to large droplets |

| Pressure Drop | Low | Moderate to high, based on design |

| Gas Velocity | Moderate | High |

| System Footprint | Compact | May require more space |

| Maintenance | Minimal | Application-dependent |

Applications and Industry Fit

Demister Pads Are Commonly Used In:

- Petrochemical distillation towers

- Gas scrubbers

- Seawater and brine desalination systems

- Absorption towers and separator vessels

For these standard applications, custom demister pad solutions provide effective mist removal at a lower cost and with minimal design complexity.

Mist Eliminators Are Commonly Used In:

- Sulfuric acid plants

- Ammonia and urea production

- Utility and industrial boilers

- Fine chemical and pharmaceutical manufacturing

In high-performance systems where finer mist particles must be removed, mist eliminators deliver higher efficiency and compliance with environmental discharge limits.

How to Choose the Right Mist Control Technology

Selecting between demister pads and mist eliminators depends on multiple process-specific factors:

- Droplet size and mist loading

- Gas flow rate and system pressure

- Allowable pressure drop

- Maintenance intervals

- Regulatory and emission requirements

- Available installation space

Demister pads are well-suited for general-purpose mist control where large droplets are present, and pressure drop must be kept low.

Mist eliminators, on the other hand, are the better choice for demanding processes that require fine mist removal or are subject to tight emissions regulations.

Why Work with Reputable Demister Pad Manufacturers?

Not all mist elimination technologies are created equal. Partnering with knowledgeable demister pad manufacturers ensures that your system is designed and fabricated with your process in mind.

At Kimre™ Clean Air technology, we specialize in providing:

- High-efficiency demister pads tailored to your flow rates, vessel design, and chemical environment

- Custom-engineered mist eliminators for high-velocity and high-efficiency applications

- CFD-supported designs to optimize flow dynamics and capture efficiency

- Proven solutions for both new systems and retrofits

As global demister pad suppliers, we serve industries in more than 40 countries with a commitment to engineering excellence, material quality, and process performance.

Future Trends in Mist Elimination Technology

The field of mist control continues to evolve with advancements aimed at improving performance, durability, and integration with modern systems. Current and emerging trends include:

- Hybrid mist eliminator designs that combine the benefits of mesh, vane, and fiber separation

- Advanced polymer and corrosion-resistant materials for aggressive chemical environments

- Real-time performance monitoring and diagnostics to track fouling or maintenance needs

- Computational Fluid Dynamics (CFD) modeling for precision engineering and performance forecasting

Kimre continues to lead innovation in mist control technologies, working closely with customers to deliver solutions that meet both today’s requirements and tomorrow’s challenges.

Finding the Right Fit for Your Process

Both demister pads and mist eliminators play vital roles in controlling mist and ensuring efficient gas-liquid separation. Choosing the right solution depends on your process conditions, performance requirements, and long-term operational goals.

Whether you're seeking custom demister pad solutions for a gas scrubber or an engineered mist eliminator for a high-velocity system, Kimre delivers performance-driven, engineered solutions that align with your plant's specific needs.

Contact Kimre for Engineered Mist Control Solutions

As trusted demister pad suppliers and mist eliminator manufacturers, Kimre brings deep experience, proprietary technologies, and engineering support to every mist elimination project.

Contact us today to speak with a technical specialist and learn how we can improve your mist control system for maximum efficiency and compliance.