In industrial vapor–liquid separation systems, removing fine liquid droplets from high-velocity gas streams presents a deceptively complex engineering challenge. Even minimal liquid carryover can accelerate corrosion, foul downstream equipment, reduce mass-transfer efficiency, and introduce regulatory risk. For this reason, the mesh pad mist eliminator remains a critical internal component across chemical processing, refining, and power generation applications.

A mist eliminator mesh is not a commodity material. Its performance depends on engineered decisions related to wire material, wire diameter, mesh density, and knit geometry. These factors directly influence droplet capture efficiency, pressure drop, drainage behavior, and long-term operational reliability. This is why properly designed mist eliminator pads continue to be trusted by process engineers operating under demanding conditions.

What Is a Mist Eliminator Mesh Pad?

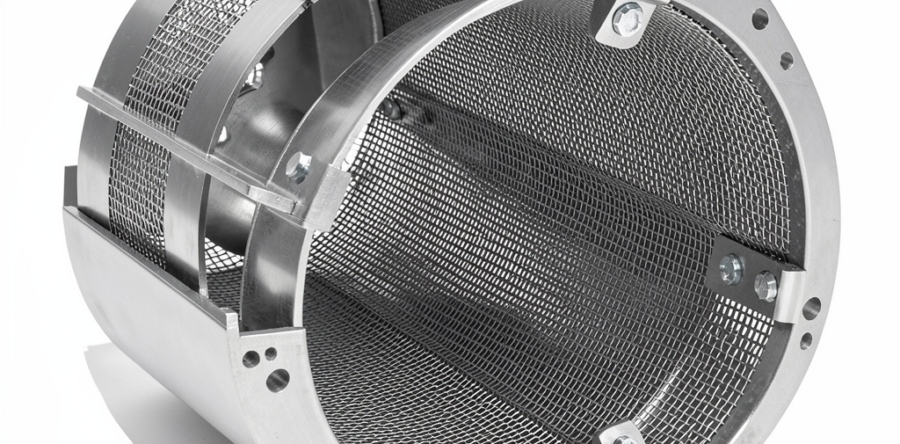

A mist eliminator mesh pad consists of multiple layers of interlocked metallic or polymeric filaments formed into a porous, three-dimensional structure. Installed within vessels, scrubbers, absorbers, or columns, the mesh creates a tortuous flow path that forces the gas stream to repeatedly change direction.

As entrained droplets contact the wire surfaces, gas–liquid coalescence occurs. The coalesced liquid drains from the mesh pad under gravity, while the cleaned gas exits the system. Unlike filtration media, knitted wire mesh mist eliminators rely on controlled inertial effects rather than pore blockage, allowing predictable pressure drop when properly sized.

How Mist Eliminator Mesh Captures Liquid Droplets

As vapor flows through a mesh pad mist eliminator, liquid droplets possess greater inertia than the gas phase. This difference prevents droplets from following abrupt changes in flow direction, causing them to deviate from gas streamlines and impact wire surfaces.

Once captured, droplets coalesce into larger liquid masses that migrate through the mist eliminator mesh and drain away from the gas stream. Sustained performance depends on maintaining efficient drainage to prevent liquid holdup and re-entrainment.

Primary Capture Mechanisms in Mist Eliminator Pads

Three mechanisms govern droplet capture within mist eliminator pads:

- Inertial impaction, dominant for larger droplets and higher gas velocities

- Interception, effective for mid-sized droplets passing close to wire surfaces

- Brownian diffusion, contributing to the capture of very fine aerosols

Together, these mechanisms allow a properly designed mist eliminator mesh pad to remove droplets across a wide size distribution, typically down to 3–10 microns depending on operating conditions.

Wire Types Used in Mist Eliminator Mesh

Common wire materials include stainless steels, high-nickel alloys, polypropylene, and fluoropolymers. Material selection depends on corrosion resistance, operating temperature, mechanical strength, and chemical compatibility.

Metallic wires are frequently specified for high-temperature or aggressive chemical environments, while polymeric mist eliminator mesh is often selected for highly corrosive services. Experienced mist eliminator manufacturers guide material selection to ensure long service life and process reliability.

Wire Diameter and Separation Performance

Wire diameter is a primary variable in mist eliminator mesh pad design. Finer wires increase surface area and improve fine-droplet capture but introduce higher pressure drop and fouling sensitivity. Coarser wires reduce pressure loss and improve drainage but may limit removal efficiency for small aerosols.

Optimized mesh pad mist eliminator designs balance separation efficiency with acceptable hydraulic performance.

Mesh Density and Void Fraction Control

Mesh density, typically expressed as mass per unit volume, determines the available surface area for droplet capture. Higher-density mist eliminator pads improve separation efficiency but increase pressure drop.

Void fraction must be carefully controlled to maintain uniform gas flow while supporting effective coalescence. Excessively dense mist eliminator mesh can promote liquid accumulation and re-entrainment.

Multi-Layer and Graded Mist Eliminator Pads

Advanced mist eliminator manufacturers often employ multi-layer or graded-density mesh pad designs. Coarser upstream layers remove larger droplets, while finer downstream layers target smaller aerosols. This staged configuration improves overall efficiency while minimizing pressure loss and re-entrainment risk.

Drainage Behavior and Re-Entrapment Prevention

Effective drainage is critical for sustained mist eliminator performance. Proper orientation, support, and mesh selection allow coalesced liquid to exit the mist eliminator mesh pad without disrupting vapor flow. Poor drainage can lead to liquid flooding and efficiency loss.

Fouling and Plugging Risks

Fouling occurs when solids, viscous liquids, or sticky contaminants accumulate within the mesh structure. Selecting appropriate wire diameter, material, and mesh density reduces plugging risk and extends service life. Conservative design margins are often necessary in fouling-prone services.

Pressure Drop vs. Separation Efficiency

All mist eliminator pads require balancing pressure drop against separation efficiency. Excessive pressure loss increases energy consumption, while insufficient mesh density compromises droplet removal. Engineered mesh designs achieve stable separation without sacrificing system performance.

Typical Applications for Mesh Pad Mist Eliminators

Mesh pad mist eliminators are commonly used in distillation columns, absorbers, evaporators, wet scrubbers, and cooling tower exhaust systems. These applications rely on consistent mist removal to protect downstream equipment and maintain environmental compliance.

Selecting the Right Mist Eliminator Manufacturer

A successful application requires evaluating droplet size distribution, vapor velocity, liquid loading, chemical exposure, and maintenance constraints. Partnering with experienced mist eliminator manufacturers ensures the selected mist eliminator mesh aligns with process conditions and long-term operating goals.

Why Engineered Mesh Design Matters

The performance of a mesh pad mist eliminator is defined by engineering precision—from wire material and diameter to weave pattern and density. Each variable directly impacts separation efficiency, pressure drop, and operational reliability.

With decades of experience in vapor–liquid separation technologies, Kimre, Clean Air Technology collaborates closely with leading mist eliminator manufacturers to deliver engineered mesh solutions built for demanding industrial applications. Connect with Kimre to evaluate your mist eliminator mesh requirements and implement systems optimized for long-term performance.