Cooling towers achieve optimal thermal and hydraulic performance only when every component is installed and operating as designed. Among these components, the cooling tower drift eliminator plays a critical role in preventing water droplets from escaping into the atmosphere. Even advanced high efficiency drift eliminators and engineered cooling tower mist eliminator systems can underperform when installation practices fall short. These errors can lead to excessive water loss, drift emissions, regulatory non-compliance, and reduced cooling tower efficiency.

Minor installation oversights often go unnoticed during commissioning but create long-term operational inefficiencies. Understanding these common drift eliminator installation mistakes is essential for maintaining consistent drift control, protecting equipment, and ensuring reliable cooling tower performance.

How a Cooling Tower Drift Eliminator Works

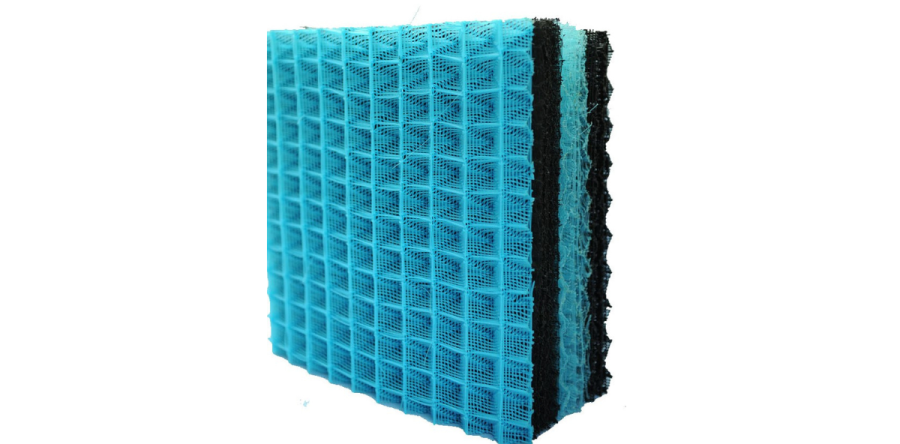

A cooling tower drift eliminator forces exhaust air through multiple directional changes that enhance droplet impaction and coalescence. As entrained droplets collide with the eliminator’s engineered surfaces, they merge, increase in mass, and return to the cooling tower basin. Proper installation ensures maximum droplet capture, minimal pressure drop, and stable efficiency for both cooling tower drift eliminator and cooling tower mist eliminator systems.

1. Incorrect Airflow Orientation and Drift Eliminator Panel Misalignment

High performance drift eliminator modules rely on precise aerodynamic pathways. Incorrect airflow orientation or panel misalignment disrupts these engineered flow channels, reducing droplet capture efficiency and increasing drift emissions. Proper alignment with the intended airflow direction is essential for maintaining the performance of any cooling tower drift eliminator system and preventing excess fan energy consumption.

2. Inadequate Sealing Between Cooling Tower Drift Eliminator Panels

Gaps, unsealed seams, or poor-fitting joints allow moisture-laden air to bypass the drift eliminator media. Even small leaks undermine the performance of high efficiency drift eliminators by enabling drift to escape without passing through the coalescing surfaces. Proper gasketing and sealing ensure that all air flows through the intended cooling tower mist eliminator pathways.

3. Using Improper Support Structures or Fasteners for Drift Eliminators

A cooling tower drift eliminator requires reliable structural support to maintain proper spacing and geometric stability. Underspecified fasteners, improper support frames, or incompatible materials can lead to sagging, vibration, and panel deformation. Such issues obstruct airflow distribution and compromise the effectiveness of high efficiency drift eliminators. Following all manufacturer specifications ensures long-term mechanical integrity.

4. Neglecting Airflow Distribution and Water Loading Balance

Uneven airflow or inconsistent water loading increases localized drift intensity and overwhelms even a well-designed cooling tower drift eliminator. Zones with excessive loading reduce coalescence efficiency, while under-loaded areas operate below design effectiveness. Adjusting louvers, spray nozzles, and distribution basins ensures uniform operation of both drift eliminators and cooling tower mist eliminator systems.

5. Insufficient Access for Drift Eliminator Inspection and Maintenance

Access limitations often lead to avoidable performance loss in cooling tower drift eliminator assemblies. Without adequate space for cleaning, inspection, and routine maintenance, drift eliminators can accumulate fouling, scale, and debris, resulting in increased pressure drop and reduced moisture capture. Designing for serviceability ensures sustained performance for all drift elimination components.

6. Mixing Old and New Drift Eliminator Components

Combining aged drift eliminators with new panels introduces inconsistent airflow resistance and unequal droplet capture performance. Older components may exhibit polymer degradation, warping, or diminished coalescing capability, compromising the efficiency of the entire cooling tower drift eliminator system. Installing uniform sets of high efficiency drift eliminators maintains predictable aerodynamic behavior and optimal drift control.

7. Ignoring Manufacturer Guidelines for Cooling Tower Drift Eliminator Installation

Manufacturers develop installation specifications based on extensive testing and performance modeling. Ignoring these guidelines leads to misalignment, improper sealing, and premature mechanical stress. Adhering strictly to the recommended installation procedures ensures that cooling tower drift eliminator and cooling tower mist eliminator systems perform at their intended efficiency levels.

Best Practices for Installing High Efficiency Drift Eliminators

- Ensure proper airflow orientation and drift eliminator panel alignment.

- Use compatible sealing materials to eliminate bypass leakage.

- Follow structural requirements for supports and fasteners.

- Maintain uniform air and water distribution across the cooling tower.

- Design for easy maintenance access to all drift eliminator modules.

- Replace drift eliminators as complete sets rather than mixing old and new panels.

- Follow all manufacturer installation and performance guidelines.

Implementing these practices ensures the long-term effectiveness of any cooling tower drift eliminator or high efficiency drift eliminator system.

Installation Precision Determines Cooling Tower Drift Eliminator Efficiency

When installed with engineering precision, a cooling tower drift eliminator delivers minimal water loss, stable thermal performance, and full compliance with environmental regulations. Kimre’s advanced high efficiency drift eliminators and engineered cooling tower mist eliminator solutions are designed for maximum durability and superior separation performance—especially when installed according to specification.

For robust, long-lasting cooling tower drift eliminator solutions engineered for peak performance, contact Kimre today.

Also read: Consequences of Drift Loss in Cooling Tower Performance and System Integrity