Mist elimination or “demisting” is the mechanical separation or removal of liquid droplets and mists from vapor streams. Failure to capture these mists effectively can lead to higher contaminant emissions, production losses, corrosion of downstream equipment, and increased maintenance.

The most common mist elimination technologies are chevron separators (also referred to as vane-type mist eliminator or vane mist eliminator) and knitted wire-mesh mist eliminators. Chevrons or vane mist eliminators are plate-type eliminators that offer high liquid handling capabilities but have limited collection efficiency for fine mist droplets below 20 microns (µm). Knitted mesh pad mist eliminators are made from wires or fibers formed into a randomly oriented mesh-pad structure.

These can capture droplets down to 3–5 microns but often have limited liquid-handling capacity and are prone to fouling from insoluble contaminants.

Mesh Pad Mist Eliminators

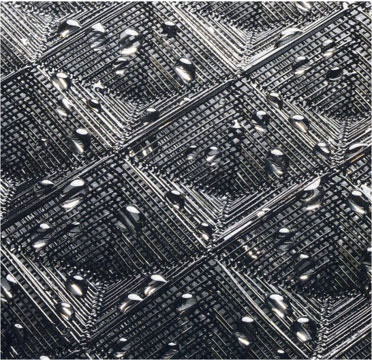

B-GON® Mist Eliminator Pads were developed using Kimre’s unique structured media to address the deficiencies inherent in existing technologies. This three-dimensional, ladder-like media is constructed from interlocking thermoplastic monofilament wires. The design orients nearly all fibers perpendicular to the gas flow, maximizing contact with entrained droplets.

This arrangement alters the vapor flow through the structure, enabling maximum mist removal through impaction, interception, and centrifugal action.

B-GON® mist eliminator mesh pads deliver the highest performance of any mesh-type mist eliminator, with efficiencies exceeding 99% for droplets as small as 1 micron. The high percentage of perpendicular fibers reduces pressure loss while maintaining efficiency equal to or greater than traditional knitted mesh pads.

Kimre produces B-GON® Mesh Pad Mist Eliminators in the industry’s widest range of fiber diameters—from 0.05 mm (0.002”) to 0.94 mm (0.037”)—and in various void fractions to meet specific flow and pressure-drop requirements. This versatility allows Kimre engineers to design custom solutions for optimal performance at any particle or mist size across a broad range of operating conditions.

|

|

| Close-up image of Kimre’s B-GON® Media | Close-up image of typical Knitted Mesh Media |

|

|

| Close-up image of Kimre’s B-GON® Media | Close-up image of Kimre’s B-GON® Media |

Features and Benefits of B-GON® Mist Eliminators

- Highest collection efficiency of any mesh-type media: 99+% @ 1 µm

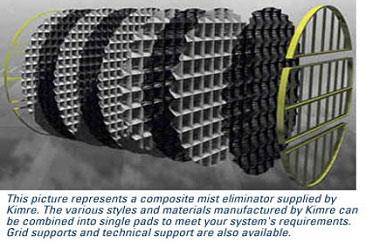

- Composite pads with various mesh styles for optimized efficiency, pressure drop, and fouling resistance

- Capable of handling the widest range of gas velocities and contaminant levels

- High void space (94–97%) and large fiber diameters for maximum fouling resistance

- Lower pressure drops than traditional knitted mesh pads

- Custom fabrication to fit any vessel configuration and orientation

- Media is cleanable and reusable for extended service life in harsh environments

- Available in a wide range of materials—including polypropylene, PVDF, ETFE, and PFA—to meet any level of temperature and corrosion requirements

Kimre’s high-performance mesh pads provide efficient solutions for air pollution control and liquid-gas separation. These advanced mist eliminators are engineered to improve operational efficiency and reduce environmental impact across various industries.