Kimre, Inc. Fiber Bed Filters are designed to provide end users with many years of optimal performance and minimal operational or maintenance requirements. We supply complete Fiber Bed Filter Systems for flow rates from 10 CFM to 250,000 CFM (15 Cubic Meters/Hr to 425,000 Cubic Meters/Hr).

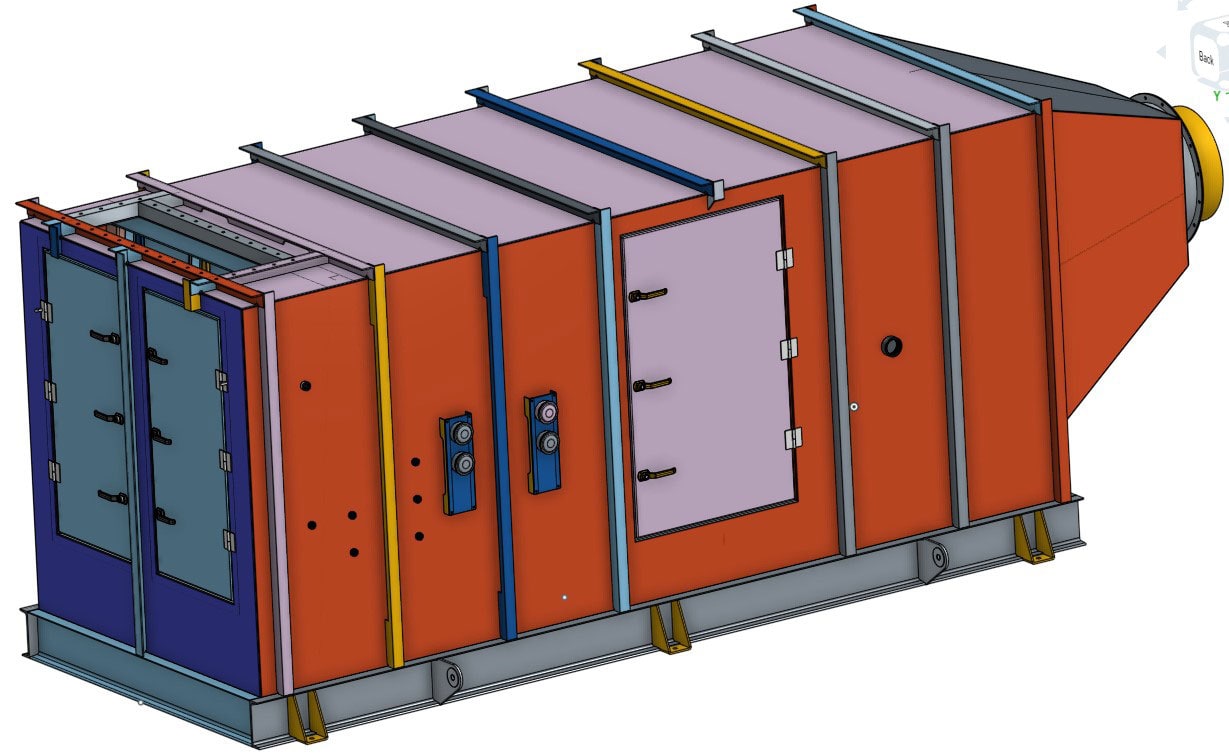

Smaller single-filter systems can be supplied with a vessel or skid-mounted fan, allowing for quick setup and connection for immediate operation. For intermediate flow ranges, we offer skid-mounted systems or separate vessels, fans, pre-filters, and exhaust stacks, tailored to site conditions. Larger systems require field assembly, which will be overseen by Kimre project engineering to ensure a successful installation.

Fiber Bed Filters are used to trap, collect, and remove liquids and soluble particulate matter suspended in a gas stream. They are also capable of collecting insoluble solids.

Particle Collection Principles

Kimre Fiber Bed Filters operate based on three primary particle collection mechanisms:

- Impaction: Large particles (>3 microns) travel within the fluid stream. While the fluid will move around obstacles, the inertia of larger particles causes them to continue along their original path, impacting the filter fibers where they are collected.

- Interception: Medium-sized particles (>1 micron) are captured when their trajectory brings them into direct contact with filter fibers.

- Brownian Diffusion: Very small particles (<1 micron) move randomly within the fluid path due to collisions with larger molecules. The smaller the particle, the greater the oscillation in its path. While these particles could bypass filter fibers, their erratic motion often shifts them perpendicular to the flow, bringing them into contact with the fiber surface where they are trapped. The collected particles then coalesce into larger droplets and drain from the filter assembly to a collecting tube sheet or bottom drain plate. Brownian diffusion offers unlimited turndown potential, and efficiencies up to 99.9% particle collection can be achieved with an average pressure drop of 2–20 inches of water column.

Fiber Bed Filter System Design

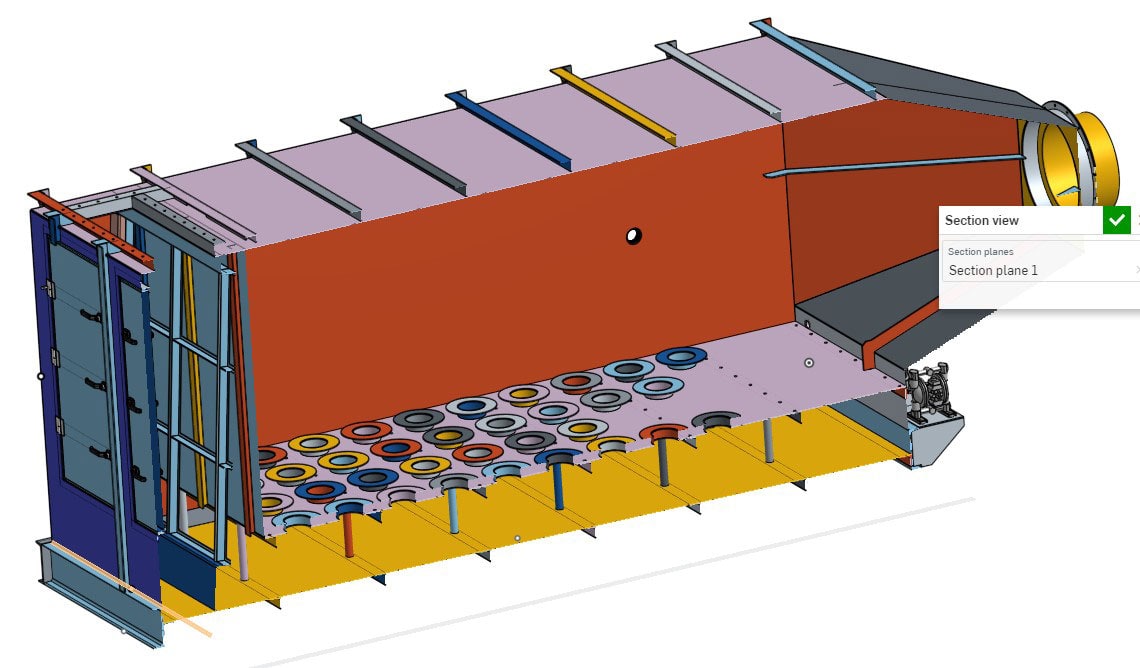

The design process begins with selecting the appropriate Fiber Bed Filter elements. The filter units either rest on or are suspended from a tube sheet inside a closed tank. Gas flow can be from the inside of the filter face to the outside (forward flow) or from the outside to the inside (reverse flow). Concentric filters combine reverse and forward flows in parallel beds within a single filter, optimizing both efficiency and pressure drop.

Integral pre-filters can be provided to enhance the performance and extend the service life of the Fiber Bed Filters. For added protection, Kimre B-GON® Mesh Pad Mist Eliminators, panel filters, or pocket filters can be installed at the system inlet. Various replacement options are available to facilitate pre-filter changes.

FAQs

How do Fiberbed Mist Collector Systems operate?

They remove particles via:

- Impaction (>3 µm): inertia-driven collision

- Interception (>1 µm): contact with fiber path

- Brownian Diffusion (<1 µm): random motion-induced capture

What industries benefit from Kimre’s Fiber Bed Filters?

Used in chemical, oil & gas, asphalt, pharma, and fertilizer industries for emission control and process protection.

What are the advantages of using Kimre Fiber Bed Filters?

- 99.9% sub-micron efficiency

- Custom designs

- Corrosion-resistant materials

- Low maintenance, long service life

- Cost-Effective Solutions

Can Kimre filters replace existing filters from other manufacturers?

Yes, they offer drop-in replacements with improved efficiency and lifespan. Kimre also offer re-packs where we use existing/used filter cages and replace with new high-performance media.

Are there options for expedited shipping?

Yes, we offer expedited shipping.

What are concentric Fiber Bed Filters?

Dual-flow (forward + reverse) filters in one unit, increasing area by 40%-60% and lowering pressure drop for compact setups.